Innovating New Aircraft Water Pipe Systems

We are constantly finding new ways to upgrade our systems and expand on our ideas. Our engineering and production teams have been collaborating in Basel to introduce a new system of water pipes for aircraft. The solution is a lighter water system that can replace the heavier tubes and will be an improvement for routine modifications.

Usually, these pipes are composed of stainless-steel tubes that are connected with fittings or welded into one flowing water system. Once we receive the steel pipes from our supplier, our teams begin the cutting and fitting attachments in the shop as well as the welding process on site in Basel, until eventually everything can be assembled together for the aircraft. However, through the joint teamwork of a team from engineering and production we are now beginning to craft the pipes from a recyclable and environmentally friendly plastic.

The system offers many new advantages, including benefitting the efficiency of maintenance services and checks for our customers. It is not designed to completely replace the metal tubing but will supplement the metal system and allow the customer to benefit from both systems – for example, metal pipes take up less space and can be used in areas with limited area.

For example, when an aircraft needs to go in for service, the new of pipes are likely to have less defects and damages than traditional materials. Norbert Antesberger, Systems Product Owner & CVE, is the product engineer at the core of this innovation. He shares that “PFA is not subject to corrosion, and the smooth inside surface of the tubing does not allow bacteria to stick to the walls. It is much less susceptible to bacteria than metal tubing. The tubing also meets the food and drug requirements of the US and is also commonly used in the food and beverage industry.”

“The system offers many new advantages, including benefitting the efficiency of maintenance services and checks for our customers.”

For a safety perspective, the tubing and fittings have also been tested against freezing and would not be damaged or leak if the water inside becomes frozen. To test this out, the tubing was frozen 20 times with no effect it. This is in comparison to the metal tubing that is destroyed during this freezing!

As well as the innovation of the material itself, the team also had to innovate new methods in which to attach the pipes to one another and mold the pipes to flow in various directions and angles.

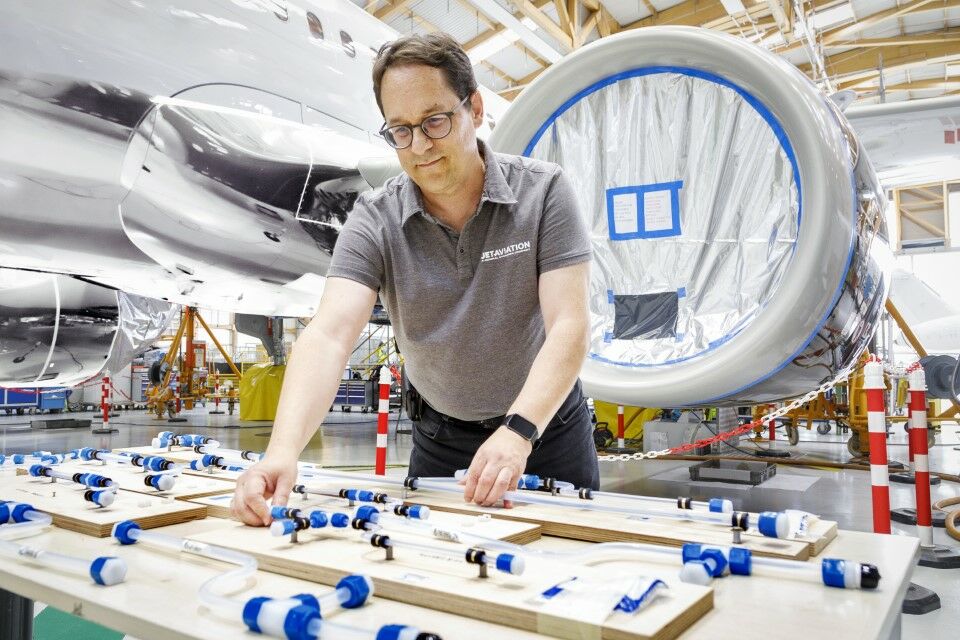

Each pipe is torqued, meaning they are indented to be easily locked into place. The pipes are then molded into the required shape by applying heat to the area. “With the flexible PFA tubing, the manufacturing of the tubing can be done on the spot by simply taking the roll of tube, bending as required, cutting to length and attaching to the end connectors by simply cutting a groove with a tool and clicking the fittings on the end" says Norbert. “For modification, it can be simply cut where needed and fittings put in. It saves a lot of time for definition of tubing and installation effort.”

In the past, metal tubing needed to be manufactured in the shop with high precision bending and detail definition of the routing. Any modification would usually require a scrap and redo of the entire tube, and thus with the new capabilities of PFA tubing “We have extended the toolbox for our water system designs," says Norbert.

The teams involved were responsible for a variety of tasks including creating the drawings and documents as well as approving documents, performing testing and providing support and guidance.

The PFA tubing with the fittings has finally been qualified for aircraft installation and will be implemented in current projects. Finally, Norbert shares, “It should also be noted that this was only the first step of the project and further improvements on different fittings, etc. will follow. The story will continue!”